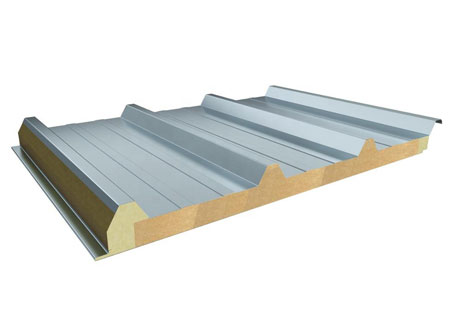

Downloading - Handling - Storage - Installation

DOWNLOADING

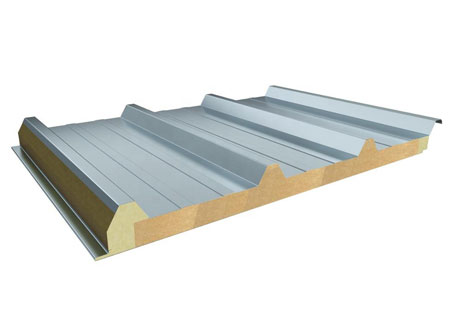

- The number of packages varies according to the characteristics of the sandwich panel or trapezoidal sheets shipped by road. Packages are separated from each other by EPS (Expanded Polystyrene) wedges. These wedges provide space for the forklift fork or crane belt to fit between the packages. It also prevents the hard contact of the panels with each other.

- It is the customer's responsibility to provide equipment and labour for unloading packages in ex-works sales. When unloading the packages from the vehicle, forklifts or cranes are used depending on their length and weight.

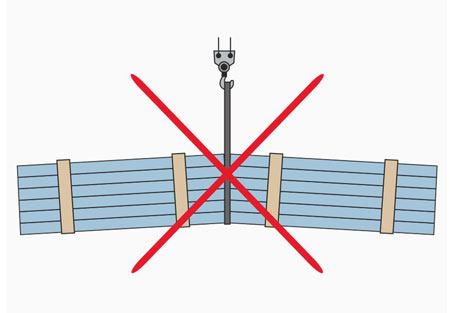

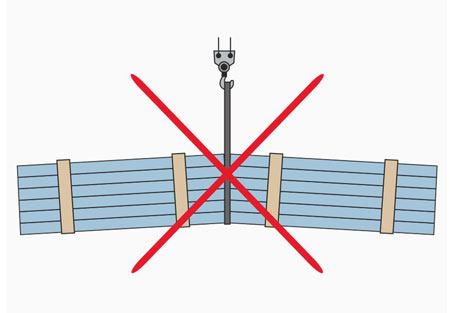

- The edges of Sandwich Panels or Trapezoidal Sheets should be well protected when lifting them to the roof. During hoisting, flat belts or counters should be used, and chains or steel ropes must never be used. When pulling the material to the roof with belts, its edges should be well protected. Care should be taken so that the pressure on the sheets does not cause deformation.

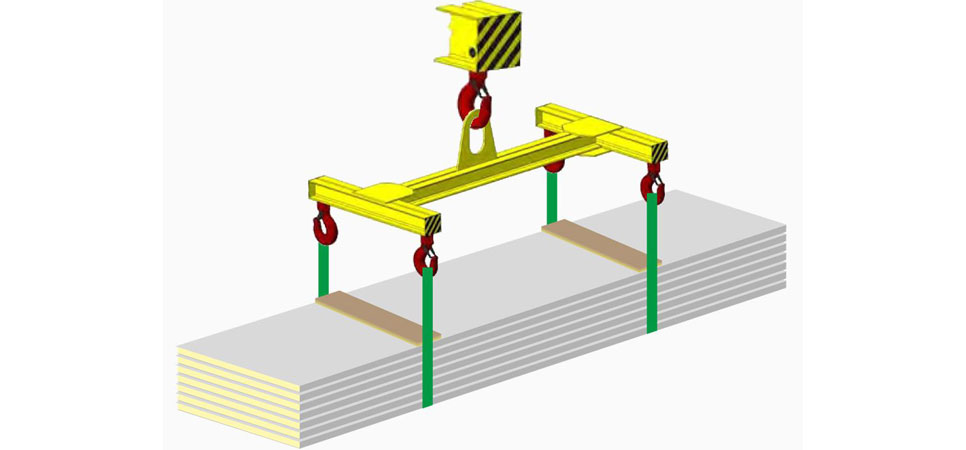

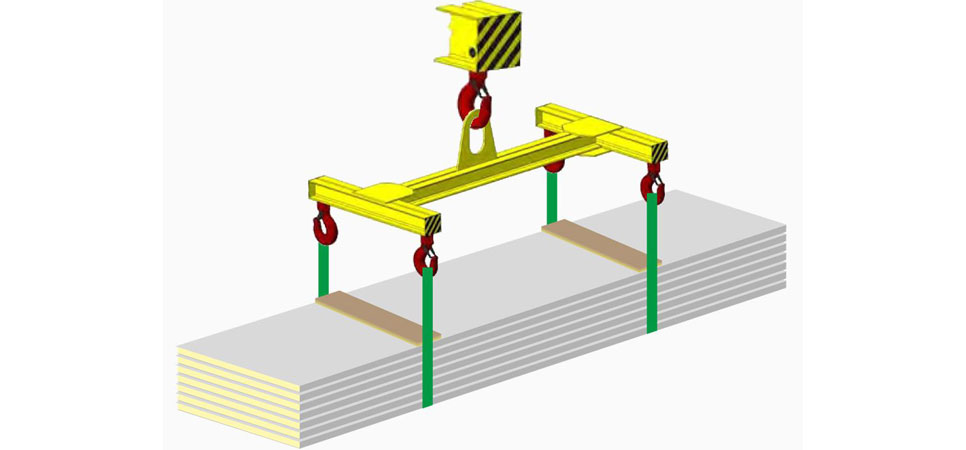

- If possible, an apparatus to spread the centre of gravity should be used under the packages.

- As pulling a trapezoidal sheet and sandwich panel from a pile should scratch the other panels, it must be taken from the pile by turning it sideways and lifting.

- While the panels are being removed from the vehicle or taken to the roof, they should not be held by the side flanges but should be held as a whole.

HANDLING

- Panels up to 6 meters can be lifted by forklift or crane. When lifting packages, if a forklift is used, care must be taken so that the bottom panels are not damaged by the forklift fork; if a crane belt is used, care must be taken so that the panel edges are not damaged by the crane belt. Panels longer than 6 meters must be lifted with a crane and a lifting beam.

- Generally, roof panels up to 15 m and facade panels up to 8 m in length can be installed with manpower. Longer panels must be installed with the help of a crane.

- When taking the panels from the package one by one, they should not be lifted by dragging them over each other, and the corners should be prevented from scratching the panel underneath. While carrying the panels, they should not be lifted by holding the side edges or metal flanges, it may cause deformation.

- If the panels have protective foils on them, they should be removed immediately after the installation of the panel. If the panels need to be stored for a long time, it is recommended to wait for a maximum period of 2 weeks. Otherwise, the protective foil will stick on the metal under the influence of the sun and cannot be removed afterward.

STORAGE

- On site, panels are often stored for a while before installation. Storage should be done by taking the following precautions.

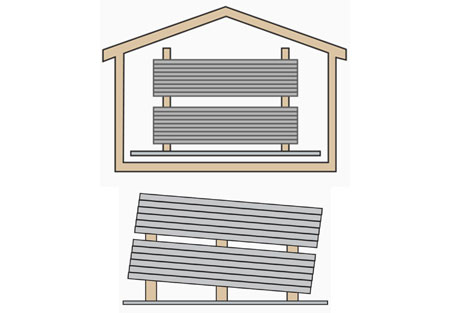

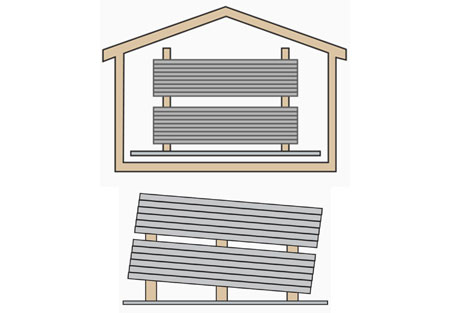

- Packages should be placed 2 meters apart on wooden wedges. EPS wedges between the packages should be used here as well, and care should be taken to keep the overlapping wedges aligned.

- Packages should be stacked in an inclined manner to prevent rainwater from accumulating on top of the packages and getting inside.

- Packages should be stored indoors.

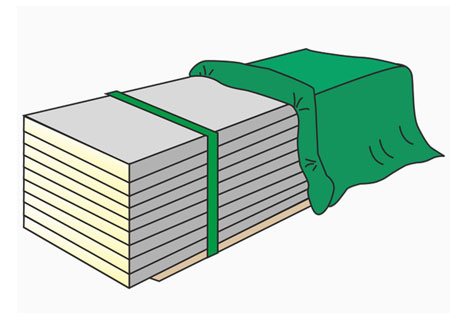

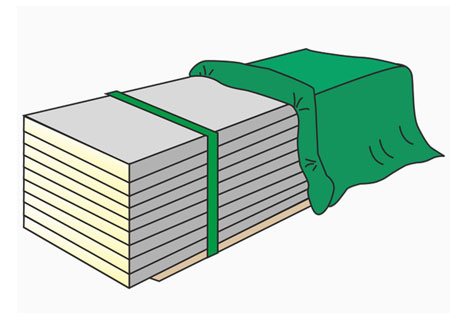

- If the packages are not protected in a covered area, they should be wrapped in a waterproof cover so that they do not form a pool. But at the same time, care must be taken to leave a gap for air circulation between the cover and the panels.

- Packages should be checked whether they absorb moisture or water despite the precautions taken.

- Care should be taken to ensure that the panels are stored in a safe area against theft and impact and that they are not on the passageways.

- Before and during the installation, the contact of the plates or panels with substances such as soil, lime, mortar, fertilizer, acid, salt, and alkali that may cause corrosion should be prevented.

- Operations that will create scratches on the material should be avoided. Plates or panels should not be left in areas where it is possible for someone to walk on them.

INSTALLATION

- Sandwich panels prepared in desired lengths are shipped to the construction site by trucks or lorries.

- Roofing materials are usually taken to the roof with the help of a crane. Care should be taken to spread the packages on the roof surface so that they do not cause a concentrated load. Packages should also be firmly tied against flying off in the wind. If the roof slope is high enough to cause the panels to slide, measures should be taken against sliding.

- The accessories that should remain under the roof panel (lower ridge, eave flashing, w-valley, off-set cleat, etc.) are mounted before the panel.

- Gloves should be used to prevent cuts and injuries.

- Installation personnel should always use rubber-soled shoes in order not to damage the panel surface.

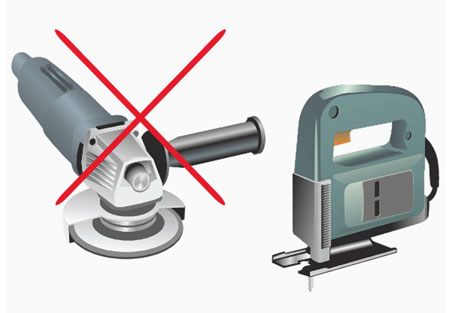

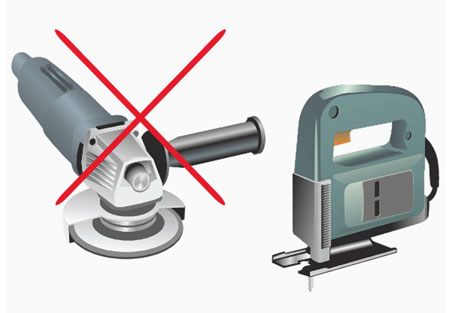

- If the panels need to be cut, either a suitable circular saw or snips should be used. In order not to damage the panel surface, the saw surface must be cold.

- Painted surfaces must be protected while welding or cutting.

- Metal wastes generated during cutting and drilling should be swept away with a brush immediately. Otherwise, they may cause corrosion within a few months.

- When working on the roof, flat work shoes with rubber soles and a walking plank should be used to prevent the crushing/collapsing of plates or panels.

- The number of screws required in installation is determined by the wind conditions and the amount required by the details. The number of screws used should not be less than 3 per square meter on the roof panel and 1.5 on the facade panel.