Büyükkayacık Osb Mah. 7. Sok. No: 11/1 Selçuklu/Konya

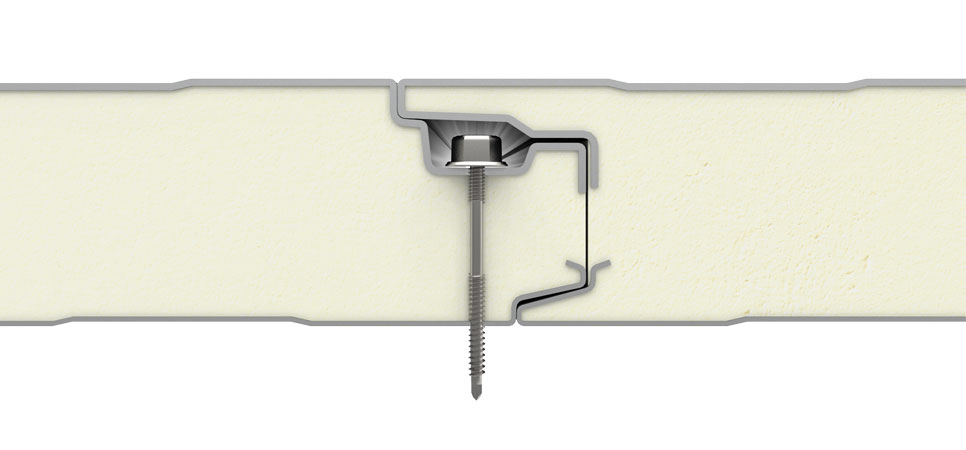

The most important feature of our concealed fastener façade panels that we produce as Mekpan Panel is that the screw joints are not visible from the outside. It provides an aesthetic appearance and is economical. It provides high insulation in buildings by allowing easy horizontal and vertical mounting. It is watertight, protects from heat and noise thanks to its PUR insulation feature, and ensures safety at the highest level by preventing flaming in case of fire thanks to its PIR insulation.

| Place of Use | Facade |

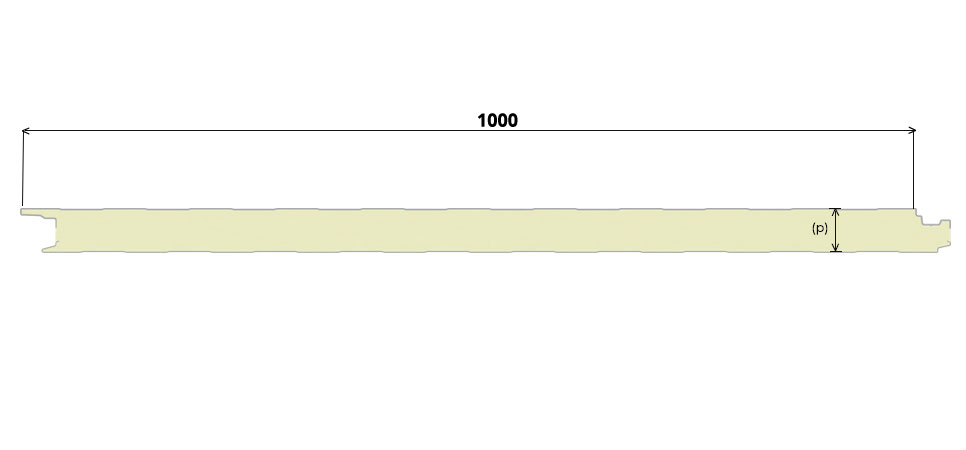

| Useful Width | 1000 mm |

| Minimum Length | 2,4 m |

| Maximum Length | Depends on Shipping Conditions |

| Polyurethane Density (EN 1602) | 40 (±2) kg/m³ |

| Polyurethane Thickness | 40-50-60-80 mm |

| Fire Classification (EN1350) | B, s2, d0 |

| Type Of Metal | Painted Galvanized Sheet |

| Standard External Metal Thickness | 0,50 mm |

| Standard External Metal Thickness | 0,40 mm |

| PGSS | PGSS | PURLING SPACING | ||||

| Top Metal Thickness (mm) | Bottom Metal Thickness (mm) |

PUR (mm) |

100 cm | 150 cm | 200 cm | 250 cm |

| 0,50 | 0,40 | 40 | 261 | 182 | 121 | 250 |

| 0,50 | 0,40 | 50 | 302 | 215 | 149 | 121 |

| 0,50 | 0,40 | 60 | 337 | 263 | 179 | 134 |