Büyükkayacık Osb Mah. 7. Sok. No: 11/1 Selçuklu/Konya

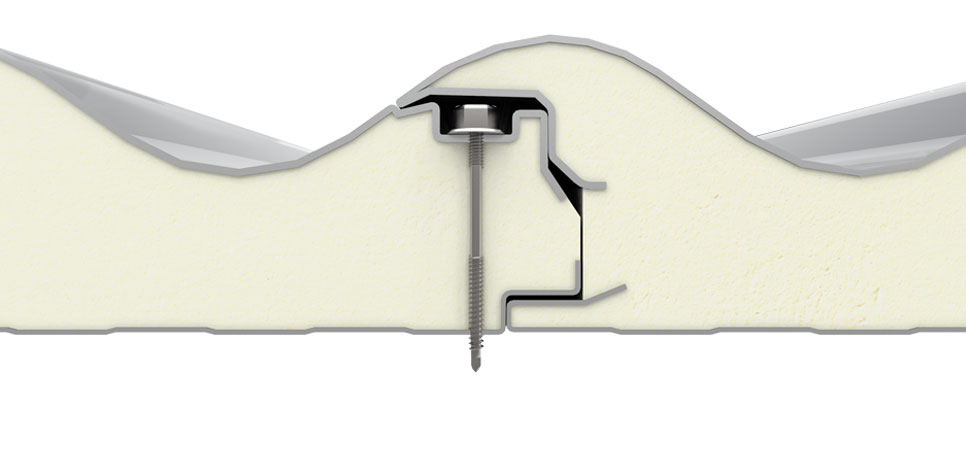

Our sinus concealed fastener façade panels, production of which pioneered by us in Turkey, offer aesthetically new solutions for your buildings in terms of technique and appearance. Our sinus façade panels offer a wide range of options to our customers in the desired colour and form. It protects against water, heat and noise thanks to its PUR insulation and it ensures safety against fire at the highest level thanks to its PIR insulation.

| Place of Use | Facade and Roof |

| Useful Width | 1000 mm |

| Minimum Length | 2,4 m |

| Maximum Length | Depends on Shipping Conditions |

| Polyurethane Density (EN 1602) | 40 (±2) kg/m³ |

| Polyurethane Thickness | 50 - 60 mm |

| Fire Classification (EN1350) | b, s2, d0 |

| Metal Type | Painted Galvanized Sheet |

| Standard External Metal Thickness | 0,50 mm |

| Standard External Metal Thickness | 0,40 mm |

| PGSS | PGSS | PURLING SPACING | ||||

| Top Metal Thickness (mm) | Bottom Metal Thickness (mm) |

PUR (mm) |

100cm | 150cm | 200cm | 250cm |

| 0,50 | 0,40 | 50 | 302 | 215 | 149 | 121 |

| 0,50 | 0,40 | 60 | 337 | 263 | 179 | 134 |