Büyükkayacık Osb Mah. 7. Sok. No: 11/1 Selçuklu/Konya

Sandwich panel metal surfaces consist of a combination of core sheet metal, galvanized, and organic coatings. Especially the organic coating increases the material life by offering good performance in corrosion resistance.

Depending on the type and degree of corrosion, the metal surface thickness of the sandwich panel facing the outside is in the order of 45 μm, of which 25 μm is organic coating and 20 μm is galvanized coating.

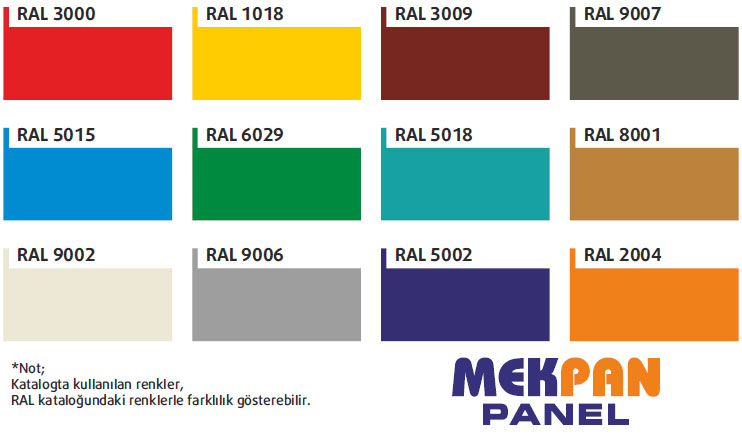

However, this thickness may increase up to 200 μm depending on the expectations. In addition, high resistance against UV, chemical, temperature, humidity, and physical effects is required from organic coatings. In addition, the wide colour scale offered by organic coatings provides styling and design advantages in architectural solutions.

Coating materials are divided into 3 groups as liquid coating, film coating, and powder coating. Wide varieties of quality and colour topcoats used on galvanized sheet metals or aluminium are preferred according to their usage areas and expected properties.

Polyester: It provides high resistance to external environmental conditions, high flexibility, and temperature balance. It is the most widely used paint type. It can be used indoors and outdoors for different purposes.

PVdF: It provides high resistance to external environmental conditions, high corrosion resistance, and resistance to chemical oils. It shows high resistance against chemicals and UV rays. It is the type of coating with the highest colour permanence and gloss resistance. It can be used as roof and facade cladding in prestigious structures.

Plastisol: It has the ability to take perfect form. It is resistant to moisture and abrasion and may be preferred in applications required to comply with food regulations. It shows superior performance in cold, humid climatic conditions.

PVC Film: It is applied by the lamination method. It is suitable for intensive shaping and flexibility. Thanks to its hygienic and easy-to-clean feature, it can be preferred in applications complying with food regulations.

CORROSION RESISTANCE

| PAINT | SCRATCH RESISTANCE |

SALT |

MOISTURE | AVERAGE THICKNESS | HEAT RESISTANCE |

| Polyester | 2800 gms | 500 h | 1000 h | 25 |

120°C |

| PVDF | 3000 gms | 500 h | 1000 h | 27 | 120°C |

| Plastisol | 3500 gms | 1000 h | 1000 h | 100-200 | 60°C |

| PVC Film | 3500 gms | 1000 h | 1000 h | 200 |

60°C |